Introduction

From (Kalpakjian & Schmid, 2016):

After a part or a component is manufactured, all or specific areas of its surfaces may have to be further processed in order to impart certain specific properties and characteristics. Surface treatments may be necessary to:

- Improve surface roughness, appearance, dimensional accuracy, and frictional characteristics;

- Improve resistance to wear, erosion, and indentation (such as the slideways in machine tools; surfaces susceptible to wear; and shafts, rolls, cams, gears, and bearings);

- Control friction in contacting surfaces of tools, dies, bearings, and machine ways;

- Improve resistance to corrosion and oxidation, which is of particular concern with sheet metals for automotive or other outdoor uses, gasturbine components, and medical devices;

- Improve fatigue resistance, as with bearings and shafts; and

- Impart decorative features, color, or special surface texture.

Surface Treatment Processes

Several processes are used for surface treatments, based on mechanical, chemical, thermal, and physical methods.

| Process | Description |

|---|---|

| Shot peening, water-jet peening, and laser shot peening | The surface of the workpiece is impacted repeatedly with cast-steel, glass, or ceramic shot (small balls). they make overlapping indentations on the surface, inducing plastic deformation of the surface, to depths up to The process imparts compressive residual stresses on the surface, thus improving the fatigue life of the component. |

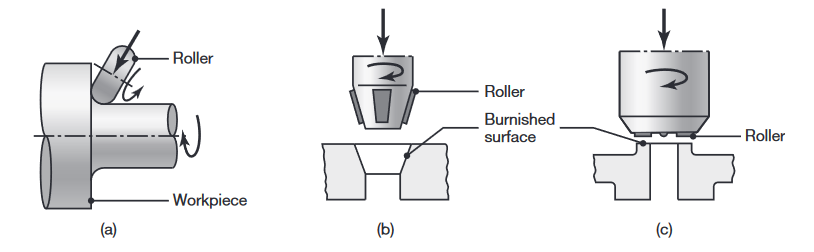

| Roller burnishing (surface rolling) | The component surface is cold worked using a hard and highly polished roller or a series of rollers |

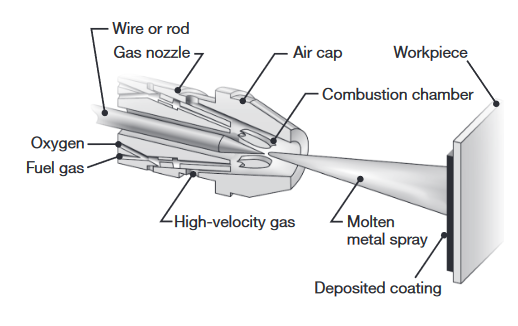

| Thermal spraying (metallizing) | Metal in the form of rod, wire, or powder is melted in a stream of oxyacetylene flame, electric arc, or plasma arc, and the droplets are sprayed onto a preheated surface at speeds up to The surfaces to be sprayed may be roughened to improve bond strength. Bond strength of Combustion spraying – oxyfuel flame or detonation gun (controlled and repeated explosions), medium strength. In Electrical spraying – arc or plasma, yields good strength. In cold spraying – the particles to be sprayed are not melted, minimal oxidation |

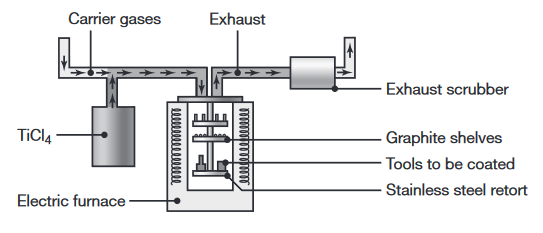

| Vapor deposition | The workpiece is surrounded by chemically reactive gases that contain chemical compounds of the materials to be deposited. The coating thickness is a few In physical vapor deposition (PVD), the process is carried out in high vacuum and temperatures in the range of In chemical vapor deposition (CVD) the tools are placed on a graphite tray and are heated to Heating – 3 hours, coating – 4 hours, cooling – 6-8 hours. |

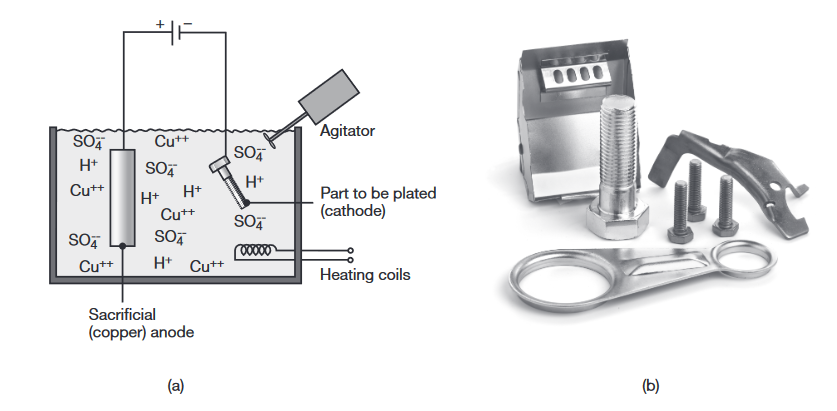

| Electroplating | The workpiece (cathode) is plated with a different metal (anode) while both are suspended in a bath containing a waterbase electrolyte solution. |

| Electroless plating | The process is carried out by chemical reaction without the use of external source of electricity. The coating has excellent wear and corrosion resistance, and has a uniform thickness. |

| Hot dipping | The workpiece (usually steel or iron) is dipped into a bath of molten metal, such as zinc, tin, aluminum (aluminizing), and terne. Hot-dipped coatings on discrete parts or sheet metal provide galvanized pipe, plumbing supplies, and numerous other products with long-term resistance to corrosion. |

| Anodizing | Anodizing is an oxidation process whereby the workpiece surfaces are converted to a hard and porous oxide layer that provides corrosion resistance and a decorative finish. |

| Diffusion coating | In this process, an alloying element is diffused into the surface, thus altering its properties; the elements can be in solid, liquid, or gaseous states. |

Examples of roller burnishing of (a) the fillet of a stepped shaft, (b) an internal conical surface, and (c) a flat surface (Kalpakjian & Schmid, 2016).

Schematic illustration of thermal wire spraying (Kalpakjian & Schmid, 2016).

Schematic illustration of the chemical vapor deposition process (Kalpakjian & Schmid, 2016).

(a) Schematic illustration of the electroplating process. (b) Examples of electroplated parts. (Shutterstock/Osipov Petr) (Kalpakjian & Schmid, 2016).